Brands We Proudly Represent

Manufactured in Taiwan by Fair Friend Ent., Co. Ltd, part of the Fair Friend Group (FFG) the worlds 3rd largest machine tool group

FEELER produces a wide range of highly reliable economically priced CNC Machining Centers and Lathes and is well entrenched in the Australian market having been represented by HS CNC for more than 20 years.

Performance Beyond Expectation.

Fixed headstock CNC Automatic Lathes manufactured in Japan by Citizen Machinery Co., Ltd. and regarded as the world leader in precision

Miyano, the bar work specialist, manufactures a range of highly productive Twin Spindle multi-turret CNC lathes that provide fast cycle times, high rigidity and exceptional reliability

Pure Miyano magic

Swiss type CNC Sliding headstock Automatic Lathes manufactured in Japan by Star Micronics Co., Ltd

Star sets the highest standards for productivity and performance and is the No.1 sliding headstock machine in the Australian market

The machine of choice for high productivity parts manufacturing

Do you have a Star on your team ?

FEELER

VMP and VMX Vertical Machining Centres

The VMP series is the popular and proven choice for the Australian market and with X-axis travel from 580 ~ 1,650mm and a wide range of options there's a model to suit virtually every applications.

The new VMX series ... focusing on the High Speed cutting market this new model features 12 & 15,000 DDS Direct Drive Spindles, and Z axis Roller Guideways combined with Intelligent Thermal Compensation monitoring to ensure the highest precision and dependability.

Vertical Machining Centres with Box Ways

The NBP and VB series engineered with solid Box Ways to all axis making the machines ideally suited to heavy duty cutting applications that require robust machine construction ability.

Available in either BT-40 or BT-50 including geared head versions ... take the NBP-1300A #50 geared head spindle delivering 470N-m of Torque at just 375 RPM.

FEELER machining muscle.

CNC Slant Bed Lathes

FEELER offers a range of Slant Bed CNC Turning Centers in both linear guide and box slideway versions, from the compact FTC-300 with Ø165mm chuck up the big 30 Kw FTC-640XL with its Ø380mm chuck and 2,000mm turning length.

Power turrets and C-axis are also available including Y-axis and sub-spindles for most models.

It's worth a look at the range.

Horizontal Machining Centers & Borers

Horizontal Twin pallet Machining Centers for production with pallet sizes 320 / 400 / 500 / 630 / 800mm.

FEELER also manufactures a large range of CNC Horizontal boring and milling machines including moving column type with X axis travel up to 4,000mm and 20 ton table load capacity.

FEELER Boring and Milling machines -

A Tradition of Excellence.

5-axis Verticals

The job doesn't have only one side so why machine only one face at a time?

U-600P and UB-660 4 + 1 axis Verticals enable cost effective multi face machining with the benefits of reduce setup time, less work in progress and increased part accuracy.

5-axis Universal Verticals available with trusted FANUC control.

Think ahead ... think 5 axis.

Double Column Verticals

Double Column Vertical Machining Centers up to 7.2 meters X axis travel and 4.0 meters between the columns SDM-M Moving column machine to 14mtrs travel.

Can be equipped with a range of horizontal, vertical and angular milling heads including automatic head attachment changer system.

Other products include Bed Mills with fixed or universal heads.

Visit the FEELER web site for more info.

MIYANO

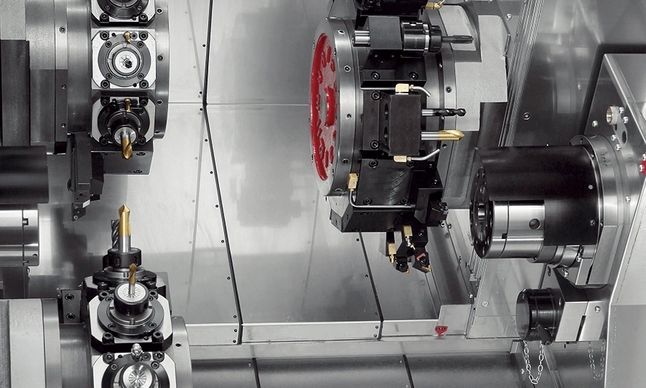

ABX series (SYY2 & THY2)

Available in twin turret or three turret versions with Y-axis to all turrets.

With bar capacity up to 64mm these high-spec twin spindle turning center provide unrestricted simultaneous machining to both the left and right spindles from either turret to achieve the shortest possible cycle time.

Driven tools and double tool holders can be mounted to any of the 36 turret tool positions providing outstanding tooling flexibility for even the most complex jobs.

The ultimate machine from the bar work specialist ... Miyano.

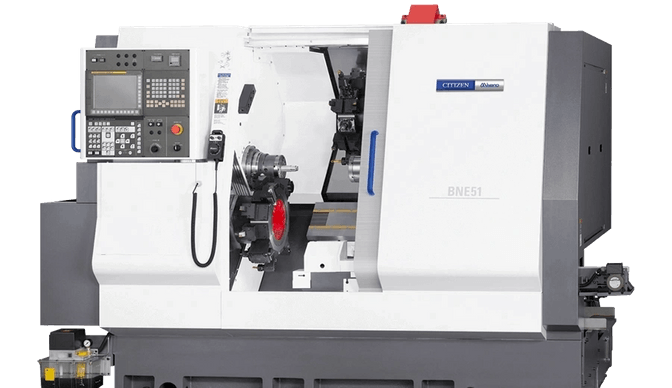

BNE & BNE-MSY series

Sixth generation of the highly successful BNE series which has long been the backbone of short cycle parts machining from bar work up to 51mm.

Twin spindle, twin turret turning centers with Y-axis on the upper turret. When combined with the use of double tool holders on the 12-station turret you will never feel short of tools.

Slant bed design combined with precision scraped square slideways ensures outstanding rigidity and extends tool life.

Revamped NC control based on Fanuc 31i and Miyano's custom menus screens.

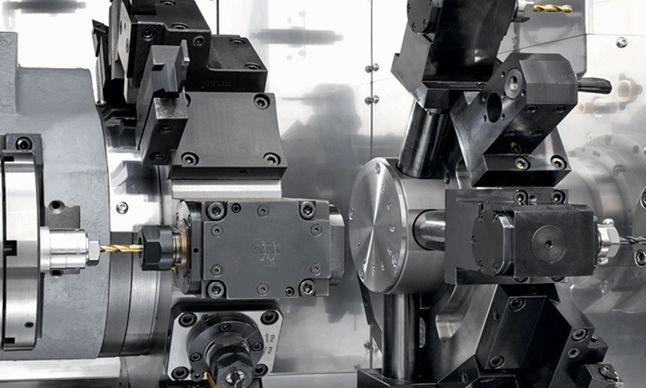

BNJ series

Up to 51mm bar capacity BNJ series delivers the benefits of overlapping machining on both spindles.

The uniquely shaped 2nd turret is fixed to the machine bed structure and when indexed to the clear side allows the sub-spindle to pass to pickup the part.

Superimposed machining whereby the movement of spindle No.2 can be overlapped with turret No.1 achieves reduced cycle times.

A wide range of options are available to support bar feed operation and unattended running.

BNJ series

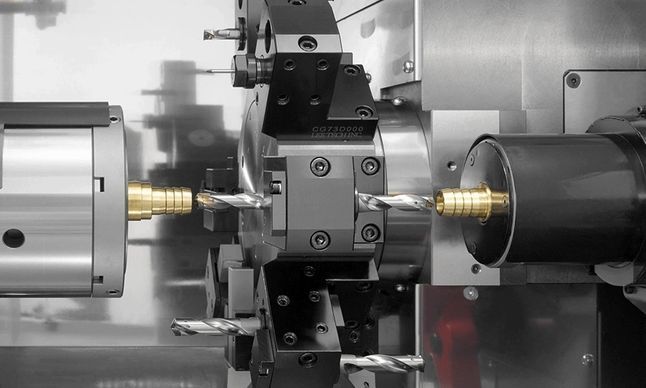

BNA series

For bar work up to 42mm , two spindles one turret and five different configurations. Sophisticated functions and high accuracy in compact body.

BNA-42S

BNA-42DHY

BNA-42SY & CY

BNA-42MSY2

BNA-42GTY

Half indexing and tool holders with multiple rotating tools at one position means you'll never feel short of tools.

Superimposed control enables spindle No.2 to overlap the machining on Spindle No.1 to further reducing cycle times.

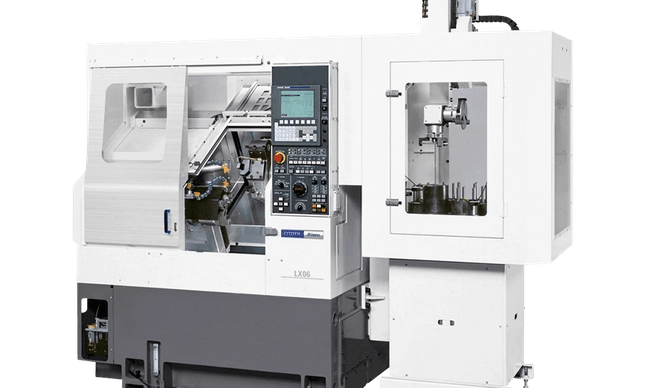

LX series

Miyano LX06 / LX08E compact 2-axis CNC lathes built on a 30 degree single casting slanted bed design and providing outstanding rigidity and thermal stability.

High rigidity turret mechanism combined with precision scraped slideways increases cutting performance making the machine most suited to Hard Turning applications.

Automatic loading devices are available such as Gantry type, In-machine loader & Double hand type.

Custom design and turn key projects can be engineered and carried out by Citizen's system engineering and applications departments.

GN series machining cells

To earn a reputation of being the "World Leader in Precision" needs a very special machine design and exceptional know-how, the Miyano GN series is one of the reason that makes this possible.

Pictured above the GN-3200W twin spindle version of the GN-3200 equipped with a high speed loader.

Various automation needs can be offered combining peripheral devices such as the high-speed gantry loader that allows selection of either one or two 2 saddles, in/out stocker, etc.

Swiss type CNC Automatic Lathes - Sliding Headstock

Non-Guide Bush option

And not just for long slender parts ... most Star lathes allow the option of Guide Bush / Non-Guide Bush switching function ideal for short parts with suitable rigidity.

Non Guide Bush version (NGB) provides material savings by substantially reducing the bar remnant.

STAR MICRONICS

SX-38 type A/B

Launching in 2020 ... The NEW SX-38

The SX-38 is a versatile, powerful and heavy-duty solution for machining complex mill-turn parts. Combining some of the best features from the SV, ST and SR series, the new SX-38 gives users the opportunity to expand their machining capabilities and maximise productivity.

The new SX-38 will launched worldwide in 2020, Check out the video and contact us for more information.

ST-38/20

Star’s flagship models packed with functionality that enables the most challenging parts to be processed.

The ST-38 & ST-20 is the ideal sliding head solution for complex mill-turn parts up to 42mm.

Three 10 station turrets can mount up to 70 tools and the main spindle lower turret includes an independent Z3 axis allowing two different features to be machined simultaneously (Z1 + Z3) using Star’s “super-position” control ability.

SV-38R / 20R

The SV-38R combines the fast processing ability of a platen type sliding head lathe with the flexibility of a turret machine.

Fanuc’s 31i-B5 control provides full 5-axis capability enabling highly complex shapes to be produced.

The 8 station back working tools and Y-axis increases machining possibilities and allows both cross working and front facing power tools to be mounted in any station.

Flexibility is further enhanced with the guide bush / non-guide bush switching function.

SW-12II / 20

The SW series delivers the highest capabilities for the machining of small work pieces up to 20mm.

Independently controlled opposing gang-type tool posts combined with Stars MOTION CONTROL system eliminates idle time to ensure the fastest possible cycle times.

SR-10 / 20RIV / 32JII / 38J

The SR Series is Star's most popular range, providing exceptional performance and versatility up to a maximum diameter of 42mm.

Available with a wide range of tooling variations including swiveling B-axis machining.

SB-series -12~20mm

Star's entry-level range of offers a great way to get started with sliding head technology.

Impressive machining versatility of the SB Series and a wide variety of options make these machines easy to accommodate and cost-effective to run.